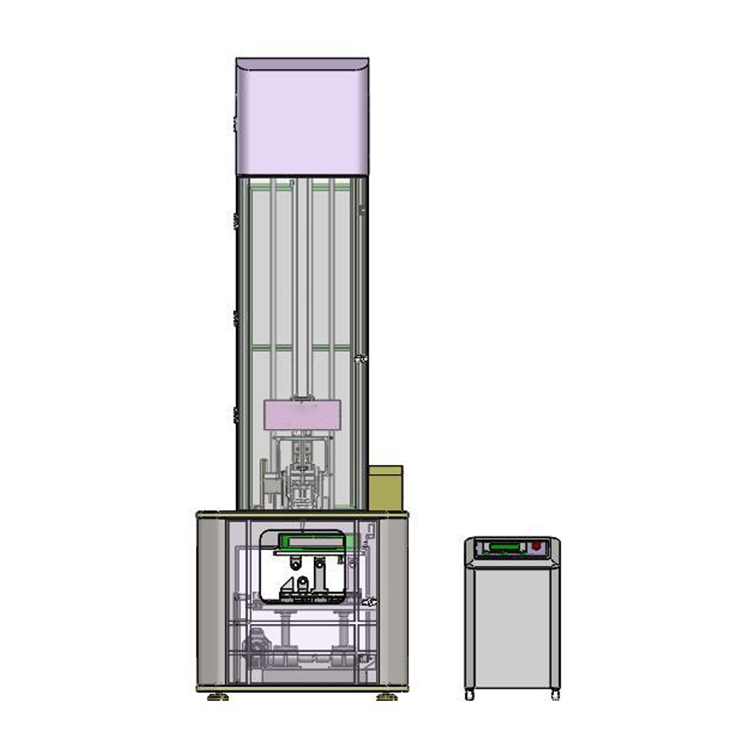

B low Temperature Impact Testing Machine(Up to 500 joules)

B low Temperature Impact Testing Machine(Up to 500 joules)

B low Temperature Impact Testing Machine(Up to 500 joules).JBDSW Impact Testing Machine used to determine the metal material under dynamic load resistance to impact performance, in order to determine the material under dynamic load properties.

Request a QuoteProduct Details

Application:

JBDSW Impact Testing Machine used to determine the metal material under dynamic load resistance to impact performance, in order to determine the material under dynamic load properties.

Standards

JJG 145-2007 PPendulum Impact Test Machine

ISO 148:1998《Metallic materials-Charpy pendulum impact test》

ISO R83 Impact test of steel (CHARPY) test (U-type notch)

ASTM E23-07a《Standard Test Methods for Notched Bar Impact Testing of Metallic Materials》

Product parameters

| MODEL | JBDSW-300CY-60 | JBDSW-450CY-60 | ||

| JBDSW-300CY-80 | JBDSW-450CY-80 | |||

| Max. impact energy(J) | 300 | 450 | ||

| Pendulum torque(N·m) | M=80.3848 | M=160.7695 | ||

| Raised angle(mm) | 150°±1° | |||

| Distance from the axis of support to the center of percussion(mm) | 750 | |||

| Impact speed(m/s) | 5.24 | |||

| Standard span(mm) | 40 | |||

| Round angle of the jaw | R (1.0~1.5)mm (1mm is special ordered.) | |||

| Angle of Taper of Supports | 11°±1° | |||

| Angle of Striking Tip | 30°±1° | |||

| Thickness of Striking(mm) | 16 | |||

| Round corner of support jaw | R (1.0~1.5)mm (1mm is special ordered.) | |||

| Blade curvature radius | R (2.0~2.5)mm (8mm is special ordered.) | |||

| Standard specimen dimension(mm) | 55x10x10 , 55x10x7.5 , 55x10x5 | |||

| Cooling way | Liquid nitrogen | |||

| Encountered an improper argument. | ||||

| Capacity of sample box | 20 | |||

| Range of low temperature | -196℃ | |||

| Speed of sending specimen | ≤2S | |||

| Power supply | 3phs, 380V/220V±10%, VAC50Hz or specified | |||

Download

| Name | Download |

|---|