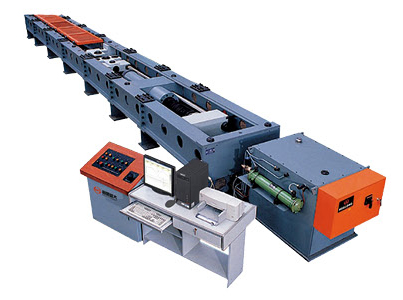

LAW-3000 microcomputer controlled electro-hydraulic servo horizontal tensile testing machine

-

Host structure:Welded frame horizontal structure;

-

Cylinder stroke (mm):1500;

-

Maximum stretch spacing (mm):0 ~ 10000 (including cylinder stroke), adjustable step by step every 500mm;

-

No-load moving speed of piston (mm/min):200;

-

Moving beam adjustment speed (mm/min):1000;

1. Product description:

This machine adopts H-shaped welding frame as stress-bearing component and hydraulic left and right bolts as space locking devices; The space adjustment device consists of gear rack and pinion and a reduction motor, and the moving trolley is adjusted step by step every 500mm; The upper part of the equipment is equipped with a safety protective cover, and the opening and closing of the protective cover is driven by a hydraulic cylinder.

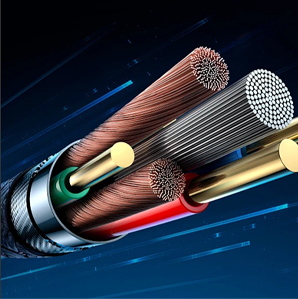

This machine is loaded by a single-outlet rod two-way oil cylinder, and can be applied to the tensile test of materials such as steel strand, wire rope, hoisting belt, chain, wire and cable, hook, wind bolt, etc. after matching the corresponding fixture. It can automatically calculate the tensile strength, yield strength, specified non-proportional elongation strength, elastic modulus and other performance indexes of the measured materials, and can complete closed-loop control such as constant rate loading, constant rate deformation, constant rate displacement and constant rate strain.

This machine is accurate in testing, powerful in function, easy to operate, stable and reliable. It is widely used in universities, scientific research institutes, testing institutions, aerospace, military industry, metallurgy, machinery manufacturing, transportation construction, construction and building materials and other industries for precision material research, material analysis, material development and quality control. Process qualification performance verification tests of materials or products can be performed.

2. Applicable standards

• GB/T 2611-2007 "General Technical Requirements for Testing Machines";

• JB/T 7406.1-1994 "Testing Machine Terminology Material Testing Machine";

• GB/T 16826-2008 "Electro-hydraulic servo universal testing machine";

• GB/T 16825.1-2008 "Inspection of static uniaxial testing machines Part 1: Inspection and calibration of force measurement systems of tensile and/or pressure testing machines";

• GB/T 22066-2008 "Evaluation of Computer Data Acquisition System of Static Single-axis Testing Machine";

• JJG 139-2014 "Tensile, Pressure and Universal Material Testing Machine";

• JB/T 6146-2007 "Technical Conditions for Extensometer";

• JB/T 6147-2007 "Technical requirements for testing machine packaging, packaging marking, storage and transportation";

• GB/T 228.1-2010 "Tensile test of metal materials Part 1: Room temperature test method";

• ASTM A370 Standard Test Methods and Definitions for Mechanical Properties Testing of Steel Products.

3. Electrical measurement and control part

(1) External independent controller

The external independent controller is developed by our company for many years-a new generation of special controller for static testing machines; It integrates measurement, control and transmission functions, highly integrates signal acquisition, signal amplification, data transmission and servo valve drive units, and adds an external manual control unit to provide a new solution for the measurement, control and operation of the testing machine. Solution, USB data transmission fully supports notebook computers, tablet computers and desktop computers; It is an important part of leading the development of testing machine technology.

(2) Measurement and control software of universal testing machineThe measurement and control software of the universal testing machine adopts DSP technology and neuron adaptive control algorithm to realize various closed-loop control modes such as constant rate test force, constant rate cylinder displacement, constant rate strain, etc. The control modes can be arbitrarily combined and smoothly switched. It has a network interface, which can realize data networking and remote control functions.

(1) Host parameters:

• Host structure: welded frame horizontal structure;

• Cylinder stroke (mm): 1500;

• Maximum stretching distance (mm): 0 ~ 10000 (including cylinder stroke), adjustable step by step every 500mm;

• Piston no-load moving speed (mm/min): 200;

• Moving beam adjustment speed (mm/min): 1000;

(2) Servo oil source parameters:

• Fuel tank volume (L): 200;

• Maximum oil pump pressure (Mpa): 28;

• Servo pump station on-load pressure rating (Mpa): 25;

• On-load rated flow rate of servo pump station (L/min): 8;

• Oil filter oil filtration accuracy (μm): 10;

• Main oil pump motor power (kW): 4;

• Overall dimensions of servo oil source (mm): 1200 * 950 * 800 (length * width * height);

• Net weight of servo oil source (kg): 320 (excluding packaging).

(3) Measurement and control parameters:

• Maximum test force (kN): 3000;

• Testing machine level: level 1;

• Effective measurement range of test force: 4%-100% F.S;

• Test force resolution: 1/500000 of the full scale (there is only one resolution in the full scale, no grading);

• Test force measurement accuracy: better than ≤ ± 1%;

• Displacement measurement resolution: 0.01 mm;

• Displacement measurement accuracy: better than ≤ ± 0. 5%;

• Deformation measurement range: 1%-100% FS;

• Deformation measurement resolution: 1/500000 of the full scale (there is only one resolution in the full scale, no grading);

• Deformation measurement accuracy: better than ≤ ± 0. 5%.

• Displacement control no-load control speed range: 0 ~ 80mm/min;

• Control methods: force closed-loop control, deformation closed-loop control, displacement closed-loop control.

5. Latch-type tooling fixture:

It is mainly used for samples with buckle type, such as steel wire ropes, slings, electric hardware and other types of samples. It can also be connected with drill pipes, chains, hooks, buckles and other types of samples.

|

Host structure Welded frame horizontal structure |

Cylinder stroke (mm) 1500 |

Maximum stretch spacing (mm) 0 ~ 10000 (including cylinder stroke), adjustable step by step every 500mm |

|

No-load moving speed of piston (mm/min) 200 |

Moving beam adjustment speed (mm/min) 1000 |

|