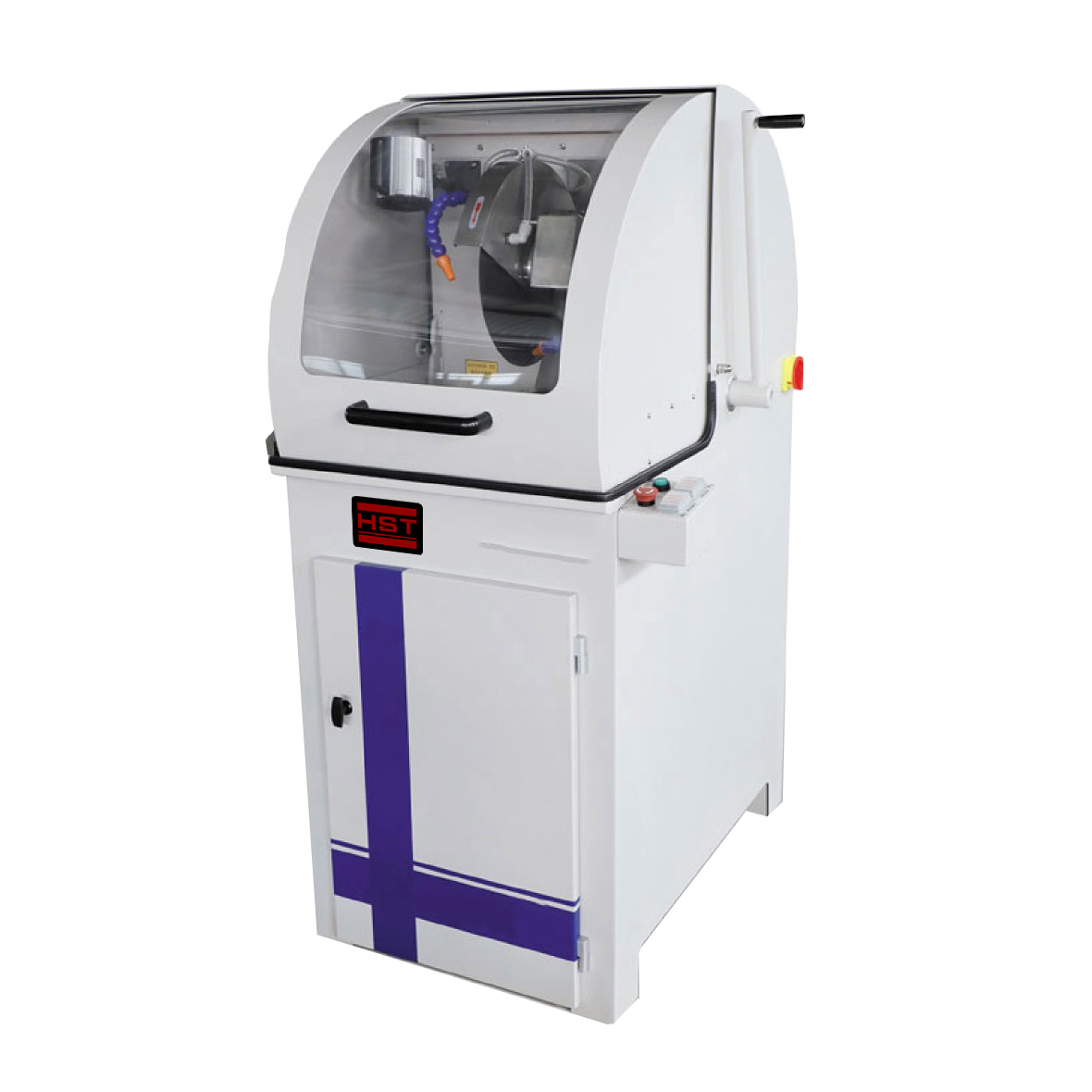

HST-Q80ZF Manual And Automatic Metallographic Specimen Cutting Machine

HST-Q80ZF Manual And Automatic Metallographic Specimen Cutting Machine

HST-Q80ZF Manual And Automatic metallographic Specimen Cutting Machine (Upright) is used to cut various metal and non-metal specimen so as to observe the material organization of Metallographic and lithofacies.

Request a QuoteProduct Details

HST-Q80ZF Manual And Automatic metallographic Specimen Cutting Machine (Upright) is used to cut various metal and non-metal specimen so as to observe the material organization of Metallographic and lithofacies.

This machine is Manual And Automatic Cutting together, it can be changed to manual or automatic arbitrarily. Under automatic operation, no need person to operate. Super-large worktable and super-length cutting distance, it could cut the big specimen.

Product parameters

|

Model |

HST-Q80ZF |

|

Cutting chamber housing |

Steel sheet |

|

The maximum cutting diameter |

80mm (pipe) |

|

Workbench Y move travel |

200mm |

|

Infeed depth tracking |

LCD Display |

|

Cutting table size |

290*300mm |

|

Cutting sheet specifications |

250*2.5*32mm |

|

Clamping table size |

Jig table left and right, center cutting edge |

|

Cutting mode |

Manual and Automatic |

|

Cutting speed |

0.1-2.5 mm/s, Automatic cutting mode can be selected: Intermittent cutting (metal work) and Continuous cutting (nonmetal parts) |

|

Gave way |

Arbitrarily set (Manual and Automatic) |

|

Infeed distance |

Arbitrarily set (0-200mm) |

|

Reset Mode |

Automatic Reset |

|

cooling system |

Automatic Water-cooled 2-channel |

|

Water tank capacity |

65L |

|

Spindle speed |

2200 r / min |

|

Motor Power |

2.2 KW |

|

Machine form |

Desktop + Cabinet |

|

Dimensions |

950*700*1500mm |

|

Cabinet dimensions |

440*440*650mm |

|

Power supply |

380V, 50Hz |

|

Weight |

260 KG |

|

1. Various cutting data can be displayed on high definition backlight type LCD screen. |

|

|

2. Manual cutting and automatic cutting means can be switched at will. |

|

|

3. Large cutting chamber, tempered glass observing window. |

|

|

4. Equipped with 60L cooling liquid water tank. |

|

|

5. Equipped with bottom support cabinet. |

|

|

6. Non-burning loss swing type cutting means which improved the cutting quality. |

|

|

7. Automatic withdraw function after cutting is finished. |

|

|

8. Bidirectional feeding means increase the length of deep cutting. |

|

Download

| Name | Download |

|---|