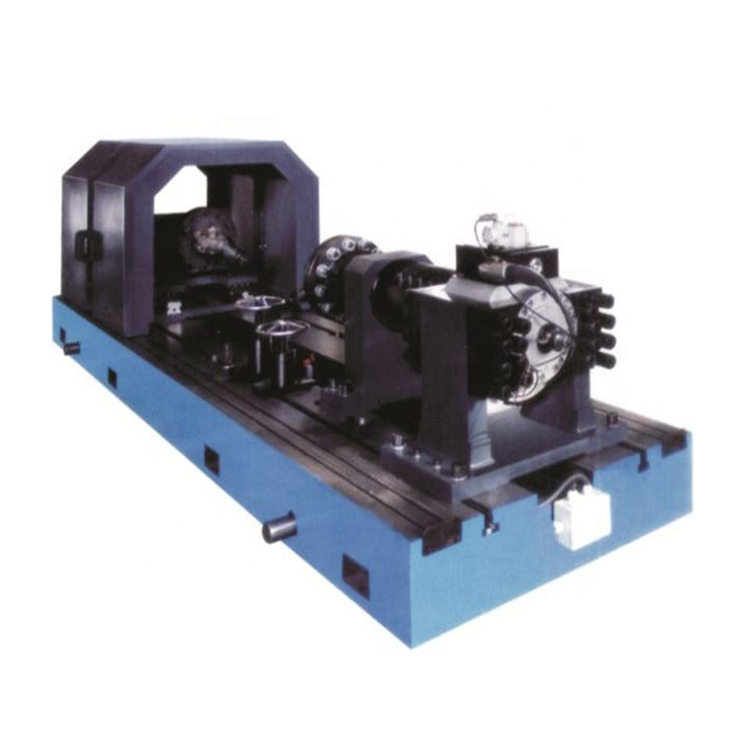

HEZ-10F Floor Type Touch Screen Metal Wire Torsion Tester

HEZ-10F Floor Type Touch Screen Metal Wire Torsion Tester

The metal wire torsion testing machine is suitable for measuring the ability of metal wire with a diameter (or characteristic size) of 1.0- 10.0mm to withstand plastic deformation in one-way or two-way torsion and to display the surface and internal defects of the wire.

Request a QuoteProduct Details

Application:

The metal wire torsion testing machine is suitable for measuring the ability of metal wire with a diameter (or characteristic size) of 1.0- 10.0mm to withstand plastic deformation in one-way or two-way torsion and to display the surface and internal defects of the wire.

This machine is mainly used for the analysis of the mechanical properties of metal wires in the mechanics laboratories of colleges, universities, scientific research departments, and industrial and mining enterprises. It is also widely used for online inspection of production units; the main industries include high-speed steel lines,prestressed steel wire plants, and quality Supervision, scientific research institutes, highway transportation,construction industry, steel wire ropes, wires and cables, copper and copper alloy wires for electrified railways, copper contact wires and other production and use departments.

Standard:

GB/T 239.1-2012 "Metallic materials - Wires - Part 1 - Test methods for unidirectional torsion";

GB/T 239.2-2012 "Metallic materials - Wires - Part 2 - Test methods for bidirectional torsion";

ISO 7800:2003 "Metallic wires - Test methods for unidirectional torsion";

ISO 9649:1990 "Metallic wires - Test methods for bidirectional torsion";

Product parameters

|

Model |

HEZ-10F |

|

Loading method |

Automatic loading |

|

Display method |

Touch screen display |

|

Wire diameter |

1.0≤d(D)≤10.0 |

|

Space between two fixtures |

500mm |

|

Jaw clamping range |

1.0≤d(D)≤10.0 |

|

Clamping block hardness |

>55HRC |

|

Torsion speed |

15-120r/min (stepless speed regulation) |

|

Speed error |

<±5% |

|

Minimum reading value of turns |

0.1 |

|

Max number of turns |

999999999 |

|

Size (L * W * H) |

1700x400x1300mm |

|

Net weight |

245kg |

|

Power |

AC 220V 50Hz |

|

Noise |

<50 dB(A) |

Download

| Name | Download |

|---|