Introduction to Compression and Crush Testing

Compression and crush testing are fundamental mechanical testing methods used to evaluate how materials and components behave under compressive forces—forces that push or squeeze a sample, potentially causing deformation, failure, or structural collapse. These tests are critical for assessing the strength, durability, and load-bearing capacity of materials in applications where they must withstand compression, such as building structures, packaging, automotive parts, and industrial machinery.

Key Definitions and Differences

- Compression Testing: Measures a material’s ability to resist compressive stress (force per unit area) before undergoing permanent deformation or failure. It focuses on gradual, controlled force application to quantify properties like compressive strength, yield strength, and modulus of elasticity.

- Crush Testing: A subset of compression testing, often involving higher or more rapid force application to simulate extreme conditions. It evaluates a material’s or component’s behavior under crushing forces, such as how a package withstands stacking pressure or how a foam cushion absorbs impact. Crush testing may focus on failure modes (e.g., buckling, fragmentation) rather than just strength metrics.

Purpose and Significance

Both tests address critical questions about material performance:

- Can a concrete block support the weight of a building?

- Will a plastic bottle retain its shape under stacking in a warehouse?

- How much force will cause a metal bracket to buckle?

By answering these, compression and crush testing guide material selection, design optimization, and quality control, ensuring products meet safety and performance standards. Poor compressive strength can lead to structural failures (e.g., collapsing shelves) or product damage (e.g., crushed electronics in transit).

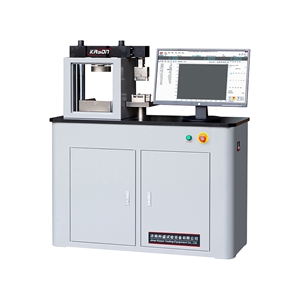

Common Testing Methods

1. Uniaxial Compression Testing

The most widely used method, where force is applied along a single axis (typically vertical) to a cylindrical, prismatic, or cuboidal sample. A testing machine compresses the sample at a constant rate (e.g., 1–10 mm/min) until failure. This method measures:

- Compressive Strength: Maximum stress before failure.

- Yield Strength: Stress at which permanent deformation begins.

- Compressive Modulus: Stiffness under compression (slope of the stress-strain curve).

2. Crush Testing for Packaging

Simulates real-world conditions like stacking or impact. For example:

- Stacking Crush Test: Measures how much weight a package can withstand when stacked with others, critical for logistics.

- Top-Load Crush Test: Applies force to the top of a container (e.g., a can or box) to determine its resistance to vertical pressure.

3. Crush Testing for Materials

Evaluates behavior under extreme compression, such as:

- Foam Crush Test: Measures energy absorption (e.g., for automotive seat cushions or protective padding).

- Particle Crush Test: Determines how easily granular materials (e.g., pills, catalyst pellets) break under compression.