Introduction to Vickers Hardness Tester

The Vickers hardness tester is a precision instrument used to measure the hardness of materials, a key mechanical property indicating a material's resistance to plastic deformation, particularly indentation. Developed in 1924 by Robert L. Smith and George E. Sandland at Vickers Ltd. in the United Kingdom, this tester has become widely adopted in industrial and research settings due to its versatility in testing a broad range of materials, from soft metals to hard ceramics, and its ability to provide consistent results across different hardness scales.

Working Principle

The Vickers hardness test operates on the principle of indentation hardness. A diamond indenter, shaped as a square-based pyramid with an angle of 136° between opposite faces, is pressed into the surface of the test material under a controlled load. After a specified dwell time to allow for plastic deformation, the load is removed, and the two diagonals of the resulting indentation are measured using a microscope. The Vickers hardness number (HV) is then calculated using the formula:

HV = 1.8544 × (F / d²)

Where:

- F is the applied load in newtons (N)

- d is the average length of the two diagonals in millimeters (mm)

The constant 1.8544 is derived from the geometry of the diamond indenter. A higher HV value indicates a harder material.

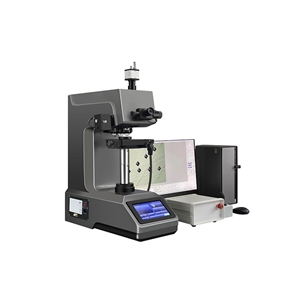

Key Components

A typical Vickers hardness tester consists of the following essential components:

- Diamond Indenter: The critical component responsible for creating the indentation. Its precise pyramid shape ensures consistent and reproducible results.

- Load Application System: Mechanism that applies and controls the test load, which can range from very low (10 gf, or grams-force) for microhardness testing to high (100 kgf) for macrohardness testing.

- Microscope: Equipped with a calibrated eyepiece or digital imaging system to measure the indentation diagonals accurately, often with a magnification of 400x for precise measurements.

- Stage: Platform that holds the test specimen, allowing for easy positioning and alignment under the indenter.

- Control Unit: Regulates the load application, dwell time, and in modern testers, automates measurement and calculation of the hardness number.