Tear Strength Test

The tear strength test is an important part of material mechanical property testing, mainly used to evaluate a material's ability to resist damage when subjected to tearing forces. It simulates the tearing situations that materials may encounter in actual use, providing key technical basis for material selection, quality control, and product design.

Importance of the Test

In many industrial fields, the tear resistance of materials is directly related to the service life and safety of products. For example, in the packaging industry, if the tear strength of packaging materials is insufficient, it may lead to packaging damage and damage to internal products; in the rubber products industry, once products such as tires and sealing rings tear, their performance will be seriously affected, and even safety accidents may occur. Therefore, accurate tear strength testing is crucial for ensuring product quality and reliability.

Applicable Materials

The tear strength test is applicable to a variety of materials, including plastic films, rubber, textiles, paper, leather, etc. Different materials have different tearing characteristics, so it is necessary to select appropriate testing methods and equipment according to the characteristics of the materials during the test.

Main Testing Standards and Methods

At present, there are various tear strength testing standards at home and abroad, and different standards are applicable to different materials and testing conditions.

- ASTM D1004: Mainly used to determine the tear strength of plastic films and sheets, using the Elmendorf method. It determines the tear strength by measuring the force required to tear a pre-notched film.

- ISO 6383-1: Applicable to the determination of tear strength of plastic films and sheets. Similar to ASTM D1004, it also uses the Elmendorf method.

- ASTM D624: Used for tear strength testing of rubber and elastomers, including three methods: trouser tear, right-angle tear, and crescent tear. The appropriate method can be selected according to the characteristics of the material and the actual application scenario.

- GB/T 16578.1: It is China's standard for the determination of tear strength of plastic films and sheets, equivalent to ISO 6383-1, and also uses the Elmendorf method.

Testing Steps

Taking the Elmendorf method for determining the tear strength of plastic films as an example, the main testing steps are as follows:

- Sample Preparation: Prepare samples of a certain size in accordance with standard requirements, and pre-cut a notch of a specified length on the sample to ensure that the tear proceeds in a predetermined direction.

- Equipment Calibration: Before the test, calibrate the tear strength testing machine to ensure the accuracy and reliability of the equipment.

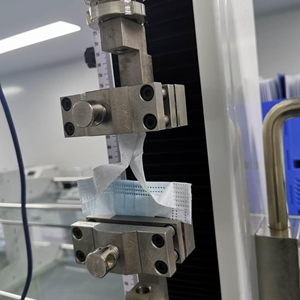

- Clamping the Sample: Correctly clamp the prepared sample on the fixture of the testing machine, so that the notch of the sample is located at the center of the fixture to avoid slippage or deflection of the sample during the test.

- Performing the Test: Start the testing machine, make the upper and lower fixtures move relative to each other at a certain speed, and apply a tearing force to the sample. The testing machine will automatically record the maximum force value during the tearing process, which is the tear strength of the sample.

- Data Processing: Based on the measured force value and combined with parameters such as the thickness of the sample, calculate the tear strength of the material according to the calculation formula specified in the standard. At the same time, conduct statistical analysis on multiple test results and take the average value as the final test result.

Factors Affecting Test Results

- Sample Preparation: The dimensional accuracy of the sample and the quality of the notch will affect the test results. An irregular notch may lead to uneven distribution of tearing force, resulting in deviations in the test results.

- Testing Speed: Different testing speeds will lead to different tear strength test results of materials. Generally speaking, the faster the testing speed, the higher the tear strength value of the material.

- Environmental Conditions: Environmental factors such as temperature and humidity will also affect the performance of materials, thereby affecting the tear strength test results. Therefore, it is necessary to control the environmental conditions within the range specified by the standard during the test.

- Equipment Accuracy: The force measurement accuracy of the testing machine and the stability of the fixture will affect the accuracy of the test results. Regular calibration and maintenance of the equipment are important measures to ensure the reliability of the test results.