ISO 604 Compressive Properties of Plastics

ISO 604 is an international standardized test method used to determine the compressive properties of rigid and semi-rigid thermoplastic or thermoset materials. Using compression platens to apply a force, the properties obtained are compressive strength, strain at compressive strength, compressive yield stress, and if required, modulus. ISO 604 is used alongside its tensile test standard equivalent, ISO 527, which together provide the fundamental material properties of polymers that are found in every industry and even every household around the globe.

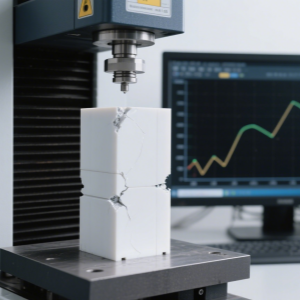

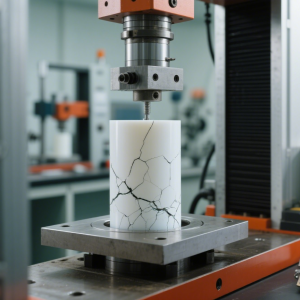

Materials Testing System

Depending on the maximum expected forces, ISO 604 can be performed on either a single column or dual column universal testing machine such as those available in Kason's universal testing machine. Compression platens with integral spherical seats are ideal for ensuring platen to platen parallelism, which is a requirement within ISO 604.

ISO 604 Platens and Accessories

Depending on your application, the following fixtures are commonly used for ISO 604 testing:

upper compression platen with integral spherical seat (diameters vary from 2" to 8”)

lower rigid platen of matching size

Strain Measurement

The preferred method of measuring strain when performing ISO 604 testing is by fixing an extensometer to the platens or the specimen itself. The instrument used must have 1% accuracy or better over the region it is being used. The fixture is the recommended strain device for ease of use, but alternatively a small gauge length (0.5 inch or less) clip-on extensometer that will fit between the platens can be used during a modulus test. However, the preferred specimen dimensions of a compressive strength test do not allow for the use of a clip-on extensometer. If not using an extensometer, nominal compressive strain is to be measured using the distance between the platens and the test frame’s crosshead position. When calculating nominal strain, machine compliance must be corrected out of the frame’s displacement measurement. A complete explanation of compliance correction can be found in an annex of ISO 604 as well as this Kason whitepaper.

Helpful Tips and Tricks

The ISO 604 method is included in the Plastics test method suite in Universal.

If the specimen is too thin, an anti-buckling support jig should be used to prevent the specimen from buckling.

If reporting the modulus calculation, make sure the extensometer and load cell are both verified in the range where the calculation is being made. Labs commonly make the error of reporting calculations outside of the verified range of their devices.