ISO 527-2: Tensile Testing for Plastics

The Definitive Guide to Performing ISO 527-2 Tensile Testing on Plastics

ISO 527-2 is an international standard for determining the tensile properties of reinforced and non-reinforced plastics. While it provides similar results to ASTM D638, ISO 527-2 is not considered technically equivalent due to differences in specimen size and test requirements. While some large multinational manufacturers test to both ASTM D638 and ISO 527-2, most of our customers demonstrate a preference for one standard or the other based on their geographical location. North American manufacturers usually test to ASTM D638 while those in Europe and Asia primarily test to ISO 527-2. Customers in China test equally to ASTM D638 and to ISO 527-2.

This guide is designed to introduce you to the basic elements of an ISO 527-2 plastic tensile test, but should not be considered an adequate substitute for reading the full standard.

HOW TO PERFORM A TENSILE TEST ON PLASTICS ACCORDING TO ISO 527-2

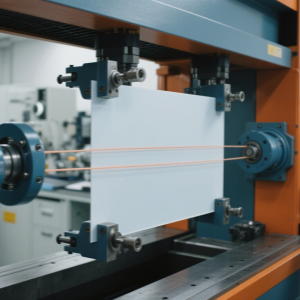

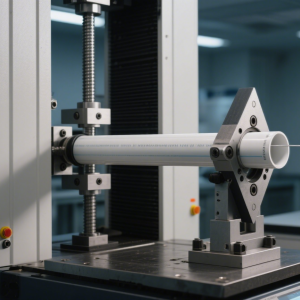

ISO 527-2 is performed on a universal testing machine by applying a tensile force to a sample (specimen) and measuring various properties of the specimen material under stress. The test is conducted at tensile rates ranging from 1 to 500 mm/min until the specimen fails (yields or breaks).

What Does ISO 527-2 Measure?

Though ISO 527-2 measures many different tensile properties, the following are the most common:

Tensile strength – the amount of force that can be applied to a material before it yields (stretches irreparably) or breaks.

Tensile modulus – how much a material can deform (stretch) in response to stress before it yields. Modulus is a measurement of the material’s stiffness.

Elongation – the increase in gauge length after break divided by the original gauge length. Greater elongation indicates higher ductility.

Poisson’s Ratio - a measurement of the relationship between how far a material is stretched and how thin it gets during the stretching process.

Is ISO 527-2 the Right Standard for You?

There are many different test methods for various types of plastics. ISO 527-2 is intended for testing rigid and semi-rigid plastics, whether molded, extruded, machined, or cast. ISO 527-2 also applies to reinforced plastics (with the exception of fiber-reinforced plastics, which are covered under ISO 527-4 and ISO 527-5). When testing films and sheets less than 1 mm in thickness, ISO 527-3 should be used. These methods and others can be found in Bluehill® Universal's Applications Modules, which contain pre-configured method templates for the most commonly used ISO and ASTM standards.

Tensile Testing Machine

Most ISO 527-2 testing is performed on a table top universal testing machine. A 5kN or 10kN (1125 or 2250 lbf) system is most common, but as reinforced plastics and composites increase in strength, higher capacity units such as 30 or 50 kN systems may be required.

Tensile Grips

Because the testing process subjects specimens to intense forces, it is important that the specimens be held securely inside of the test machine. Side-action pneumatic grips with serrated jaw faces are often the best grips for holding rigid plastics. Pneumatic grips maintain their gripping force with air pressure, which remains constant even if the specimen deforms during testing and its thickness changes significantly. For forces above 10 kN, typically only found with reinforced materials, manual wedge-action grips are preferred.