ISO 37

How to Perform a Tensile Test to ISO 37

Determining the Tensile Properties of Vulcanized or Thermoplastic Rubber

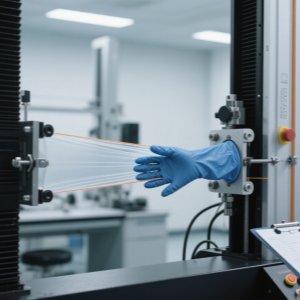

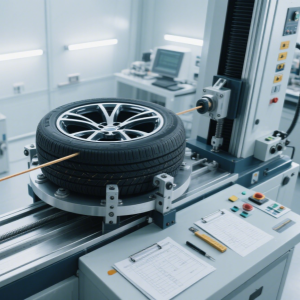

ISO 37 is used across a wide range of industries to measure the tensile stress-strain properties of vulcanized and thermoplastic rubbers. It is similar but not equivalent to ASTM D412, and most companies will test to one standard or the other depending on where in the world they are located. ISO 37 is commonly used by companies engaged in raw material manufacturing, development of elastomer technology, and manufacturing of rubber-based consumer products and medical supplies, such as rubber gloves. ISO 37 is also a very common standard used by the energy and automotive sectors, particularly tire manufacturers. This guide is designed to introduce you to the basic elements of an ISO 37 tensile test, including an overview of the equipment, software, and samples needed. However, anyone planning to conduct ISO 37 testing should not consider this guide an adequate substitute for reading the full standard.

What Does it Measure?

ISO 37 determines a material's tensile strength, elongation at break, stress at a given elongation, and yield point. The measurement of stress and strain at yield is only applicable to some thermoplastic rubbers and certain other compounds.

Materials Testing System

ISO 37 tests are performed on a universal testing machine. System capacity will depend on the strength of the elastomer, however, most tests to this standard will fall in the 1 kN and 5 kN capacity range, making this application perfect for a single column test frame. Many elastomers tested to ISO 37 are high-elongation materials, and may require an Extra Height frame.