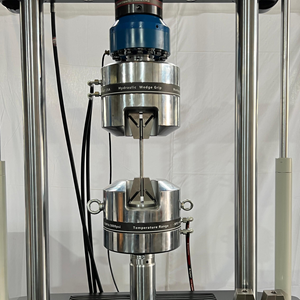

TMF Testing to ISO 12111 & ASTM E2368

The challenge

Materials exhibit different behaviors under cyclic thermal loading, similar to cyclic mechanical loading in fatigue. Applications, where materials are subject to high thermal gradients, require additional testing on top of typical static and fatigue tests. These components may be exposed to thermomechanical fatigue (TMF), where they experience cyclic mechanical and thermal loading under service conditions. Contributions of creep and fatigue to the TMF damage in structural integrity under combined thermal and mechanical loading cycles are monitored and analyzed in order to ensure safe operating conditions for the duration of the component’s life cycle.

Our Solution

Thermomechanical Fatigue (TMF) testing systems help characterize material properties under cyclic mechanical and thermal loading, which contributes to the material selection process for different applications where components are exposed to combined thermal and mechanical loading profiles, including the hot section components in gas turbine generators and jet engines.

It also allows engineers to better predict the life cycle of components under these conditions and confirm that computer simulation models correctly predict material behavior under TMF.

TMF applications and research areas include:

Characterization of materials under combined thermal and mechanical loading cycles

Effects of different loading phases on materials

TMF crack initiation in superalloys for gas turbines generators

TMF life prediction of hot section components in jet engines